Understanding the Most Popular 3D Printer Filament Types

There are a variety of common 3D printer filament types, each with strengths and weaknesses. Let’s explore the six most commonly used filaments.

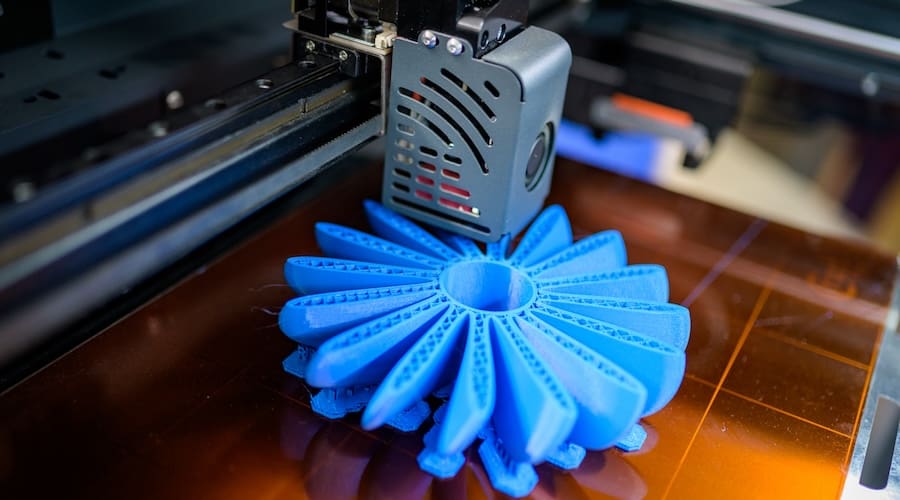

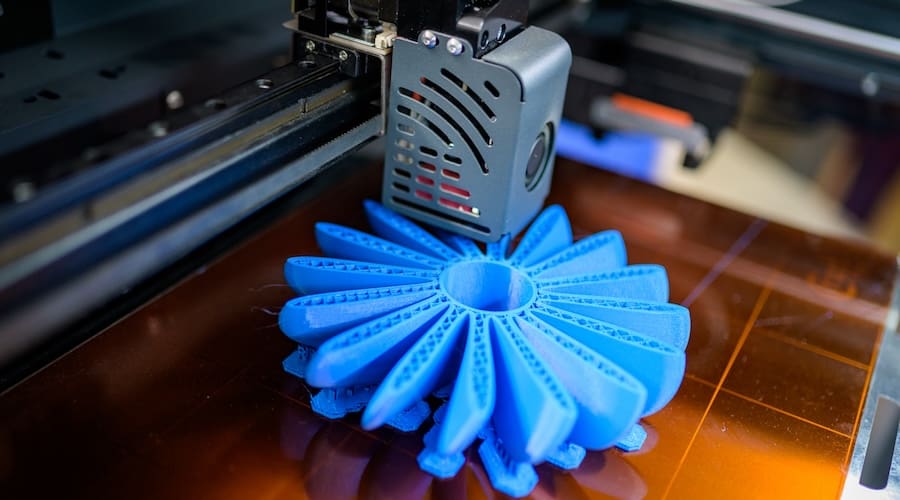

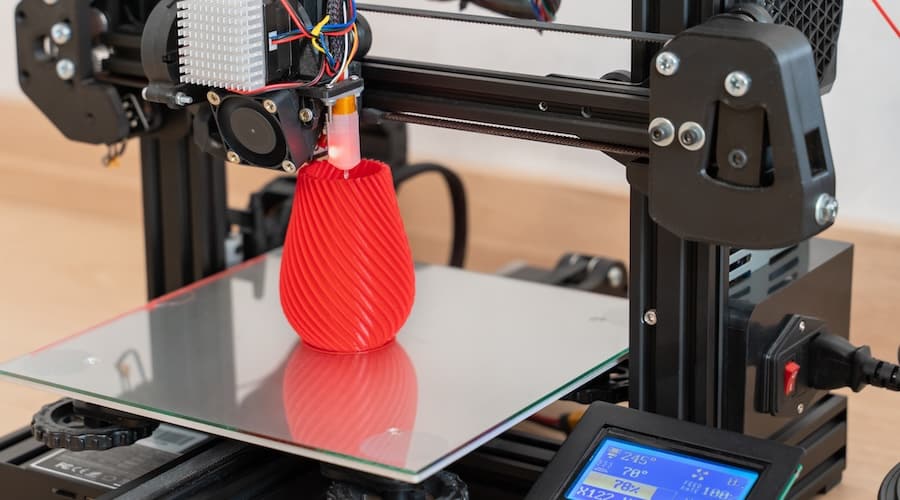

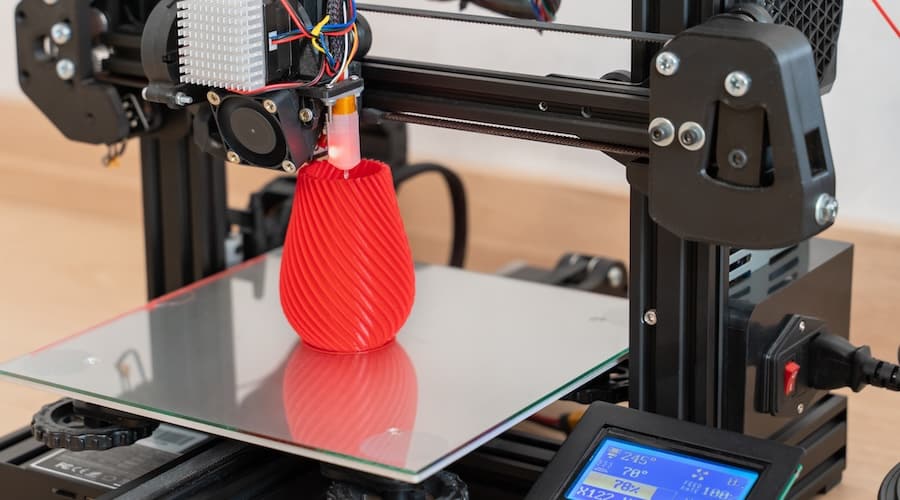

Congrats, you’ve just joined the elite club of 3D printing! Picture this: you’re now the proud owner of a magical box that turns dreams into reality. Well, sort of. Whether you’re crafting bionic arms for superheroes or tiny warriors for your epic tabletop battles, there’s one tiny detail you can’t ignore: the different types of 3D printer filament.

Think of 3D printer filament as the secret sauce in your printing recipe. It’s what keeps your 3D printing dreams from turning into 3D printing nightmares. With a smorgasbord of options out there, you might wonder, “What’s the best type of filament to use when I want to print, say, a tiny castle or a rocket ship?”

Well, fear not! We’re diving into the fantastical world of 3D printer filaments. We’ll look at the six basic types, from the garden-variety PLA and PETG to the superhero-grade stuff like nylon and polycarbonate. Some will be easy to use, while others might have you fighting clogged nozzles almost continuously without the proper settings.

With this treasure trove of filaments at your disposal, your prints can be as sturdy, flashy, or sci-fi as you like. To navigate this filament fiesta, here’s our materials guide, slicing and dicing the filament universe into digestible chunks. Get ready to find your filament soulmate!

The 6 Most Common Types of 3D Printer Filament

First, let’s review the basics of the six most commonly used materials in 3D printer filament. These are all popular for being relatively easy to use but providing physical properties needed for strength, durability, flexibility, or a combination of all of those.

The table below provides a snapshot of the characteristics each of these 3D printer filament types typically exhibit. You can use this table for a quick reference to find the best material for your particular project.

| PLA | ABS | PETG | TPE, TPU, TPC | Nylon (PA) | Polycarbonate (PC) | |

| Strength | Medium | High | High | Medium | Very high | Very high |

| Flexibility | Low | Medium | Medium | Very high | High | Medium |

| Durability | Medium | High | High | Very high | High | Very high |

| Difficulty to use | Low | Medium | Low | Medium (TPE, TPC); Low (TPU) | Medium | Medium |

| Print temperature | 180 – 230º C | 210 – 250º C | 220 – 250º C | 210 – 230º C | 240 – 260º C | 270 – 310 º C |

| Print bed temperature | 20 – 70º C (not necessarily needed) | 80 – 110º C | 50 – 75º C | 30 – 60º C (not necessarily needed) | 70 – 100º C | 90 – 110º C |

| Shrinkage/warping | Minimal | Considerable | Minimal | Minimal | Considerable | Considerable |

| Soluble | No | In esters, ketones, and acetone | No | No | No | No |

| Food safety | Refer to manufacturer guidelines | Not food safe | Refer to manufacturer guidelines | Not food safe | Refer to manufacturer guidelines | Not food safe |

Next, let’s dive into the particulars of each 3D printer filament material. We’ll start with the most commonly used, PLA.

Polylactic Acid, or PLA, is the Most Common of the 3D Printer Filament Types

PLA is a friendly neighbor in the filament community. It’s like that easygoing friend who doesn’t need fancy dinner plans — just a low printing temperature, and it’s happy as a clam. No need for a heated print bed here (although, like extra cheese on a pizza, it’s a welcome addition).

PLA’s superpower? It doesn’t stink up your workspace with weird smells. That’s right, while ABS is out there smelling like a science experiment gone wrong, PLA is busy being the unscented candle of filaments. Some users do report a whiff of sweet candy aromas, but you can just think of it as printing with Willy Wonka’s secret recipe!

But wait, there’s more! PLA is like the rainbow unicorn of filaments, available in more colors and styles than your favorite ice cream shop. From glow-in-the-dark to wood-infused varieties, it’s like a chameleon but cooler.

Now, let’s talk green. PLA is sort of like that person who recycles but also drives a gas-guzzler. It’s more environmentally friendly than many filaments, as it will biodegrade in the right conditions. But don’t plan on tossing it in your backyard compost — it’s not quite that eco-friendly. It’s like being better than some, but maybe not the poster child for green living.

What Can I (or Can’t I) Do with PLA

PLA is widely used for a ton of purposes, but it’s not a be-all, end-all for every project. It’s more brittle than other types of 3D printer filament, so you don’t want to use it to make items that might be twisted, bent, or repeatedly dropped. In other words, this isn’t the filament for your next phone case.

This type of 3D printing filament also doesn’t withstand high temperatures. Once it gets to around 60ºC or higher, PLA tends to warp and deform, melting a bit just like M&Ms after you hold them tightly too long.

The best uses for PLA include models, low-wear toys, prototype parts, and containers.

Acrylonitrile Butadiene Styrene (ABS)

ABS isn’t as popular for everyday use in 3D printing, but you might be interested to know that many of your manufactured household and consumer goods are made using it. From bicycle helmets to Lego bricks, ABS is very commonly used in commercial injection molding.

Compared to PLA in hobbyist 3D printing, ABS has some distinct advantages. Yes, it’s prone to warp without a hot print bed and some sort of print adhesive, but it is stronger, more flexible, and more durable than PLA. It’s just very tricky to work with.

See, it isn’t just that ABS requires high printing temperatures and has a tendency to warp during cooling. It also emits intense, potentially hazardous fumes. If you print with ABS, make sure you use a heated bed and a well-ventilated space. You could also print with an enclosure, of course, and vent the fumes out.

When to Use ABS 3D Printer Filament

ABS shines when making items that might be frequently handled, dropped, or heated. It’s also moderately flexible. So, you can confidently use ABS to print phone cases, high-wear toys, or automotive trim components. You could also use it to make tool handles or electrical enclosures.

PETG, or Polyethylene Terephthalate Glycol

Next up is PETG, the plastic superstar you’ve been unknowingly hanging out with all along! You know those water bottles you chug from? Those trendy clothes you wear? Those food containers you can’t seem to find lids for? Yep, you could easily find PET in each and every one of them.

In 3D printing, PET gets a little makeover, becoming PETG. Think of PETG as PET’s cooler cousin who’s just back from a gap year. The “G” stands for “glycol,” which is less of a tongue-twister than “Polyethylene Terephthalate,” and it’s like PET went to a spa — it comes out clearer, less brittle, and way easier to print with.

PETG is more flexible and durable than PLA and doesn’t have the diva demands of ABS when it comes to printing. There’s also PETT, PETG’s slightly more uptight sibling. It’s a bit more rigid but wins the prize for being the clearest of the clan. Think of it as the window glass of filaments since it can even be transparent.

But, dear 3D printing enthusiasts, here are three nuggets of wisdom for using PETG:

- PETG is a bit of a sponge — it loves moisture more than a cat loves a warm laptop. Store it in a dry place, or you might have to blow dry it before use.

- This filament is also sticky when it’s hot — great for layer love but not so great for support structures. It’s like using superglue when you need a Post-it.

- It’s not exactly the Superman of filaments; it can get scratched more easily than ABS. So maybe don’t use it for your cat’s new scratching post.

When You Should Consider PETG or PETT

PETG and PETT are ideal for printing anything that’s going to face the daily grind — think mechanical parts that move more than a jittery jackrabbit, hardworking printer components, and resilient protective gear. This filament is a real MVP, boasting a blend of strength, flexibility, and a talent for sticking together under pressure (literally).

The ‘Rubbery’ Plastics: TPE, TPU, and TPC

Thermoplastic elastomers, or TPE for short, are like the superheroes of the plastic world. Imagine a material that’s got all the stretchiness of rubber and the durability of your favorite action figure — that’s TPE! It’s so versatile, it’s found everywhere from car parts to your kitchen blender, and even in medical gadgets.

Think of TPE as a big family with lots of cousins. It’s a mix-and-match of co-polymers and polymer blends, but in the world of 3D printing, it’s like the popular kid everyone knows. TPE filaments bend and stretch in ways that would make ABS and PLA filaments gasp in shock. But, just like trying to thread a needle while wearing boxing gloves, printing with TPE isn’t always a walk in the park. It can be as tricky as convincing a cat to take a bath!

Then there’s thermoplastic polyurethane (TPU). If TPE is a yoga expert, TPU is its slightly stiffer cousin who prefers Pilates. It’s a favorite in the 3D printing world because it’s a bit easier to handle and can stand up to the cold like a penguin in a parka.

And don’t forget about thermoplastic copolyester (TPC)! It’s like the cousin who doesn’t come to family reunions as often. TPC shares a lot of qualities with its TPE relatives but shines in its ability to laugh in the face of chemicals, UV rays, and heat. It’s like the action hero of the family, able to withstand a blazing 150 °C without breaking a sweat!

When To Use TPE or Its Cousins

If you need to create an object that has to take a lot of wear, TPE or TPU is your filament. These 3D printing filaments can handle a ton of bending, stretching, or compression. TPE and TPU are great for toys, phone cases, or wearables (like watch bands). On the other hand, if your creation needs to stand up to the outdoors, be it sweltering summer temperatures or Arctic chills, TPC is a good pick.

3D Printing with Nylon

Next up, we’ve got polyamide or PA. This stuff is more commonly known as just nylon, a popular family of synthetic polymers. It’s used in a wide variety of industrial applications, as well as commercial powder-fusion 3D printing. It also excels among the 3D printing filaments where strength, flexibility, and durability are critical.

One aspect that sets nylon apart from the others is that you can dye it, either before or after you print it. This does mean, however, that it’s like PETG in being hygroscopic: it’ll soak up moisture from the air like a sponge. Make sure you store your nylon filament in a cool, dry place when it’s not in use.

Using nylon in your 3D printing is also more difficult than other filaments for a few more reasons. It’s fairly expensive, and you need to set your nozzle and print bed temperature high to prevent failed prints.

Great Uses for Nylon 3D Printer Filament

If you need to create tools or functional prototypes, nylon could be your best choice. It’s also great for crafting mechanical parts, such as hinges, buckles, and gears.

Polycarbonate, or PC, One of the Strongest 3D Printing Filaments

Imagine something that can chill at a toasty 110° C without breaking a sweat — that’s PC for you! It’s also got this natural see-through vibe, kind of like a pair of hipster glasses. That’s why you see it showing off in everything from bulletproof glass (because who doesn’t want their morning coffee shielded from stray bullets?) to scuba masks and electronic displays.

Now, let’s clear up a little mix-up: PC is not the same party animal as acrylic or plexiglass. Those two are more like the glass slippers of Cinderella — pretty but prone to drama under pressure. PC, on the other hand, is like a yoga instructor — flexible but not quite ready to twist into a pretzel-like nylon.

And here’s an important fact: polycarbonate 3D printer filament is a bit of a diva. It loves the spotlight but hates moisture, absorbing water like a gossip tabloid. So, remember to stash it somewhere cool and dry unless you’re aiming for abstract art in your prints.

Why Use Polycarbonate In 3D Printing?

PC is tough, it’s strong, and it laughs in the face of high temperatures — perfect for making anything from indestructible robot parts to car gadgets that won’t melt in the sun. Plus, it’s so clear as to be see-through, making it a top choice for lighting projects or anything else where you need to see through clearly.

The Tip of the 3D Printer Filament Iceberg

These are just the six most commonly used materials for 3D printing filament. There are other, more exotic, types of 3D printer filament. Look through what your particular model of 3D printer supports, and you might find that you could turn to one of the fancier types for a wood-like appearance, glow-in-the-dark properties, or even electrical conductivity. Those, however, are food for thought in another article.

Leave a Reply

Leave a Reply